Designed in Siemens NX6

I was asked to make tutorial of design of DAFT PUNK helmet. Now i finished it and here it is, so you can make this helmet too. Model is free for download from this page.

This tutorial do not cover electronics and assembly details, just how to model plastic parts of helmet.

To start this

tutorial, open new part.

I imported head

model, but I made mistake and used large head instead normal so this whole

helmet is oversized. To make it good it is best to measure your head and to

make model according to those measures, that way helmet will fit you good.

So here is a head,

and we can start.

Now add first sketch

in vertical plane, as you can see measures are oversized. Ral head is about

10-15% smaller (if you are not 2m high and have 150 kg), anyway this is how sketch should look like, just edit numbers so your head fit

inside this sketch.

Now second sketch:

Same as first sketch

this one is little oversized, so be careful with dimensions.

Now we have two basic sketches, and now we will start making shape of

this helmet. First make two extrusions based on these two sketches. From

vertical sketch make normal extrusion, and from horizontal make it drafted for

5-15°.

Now use Insert>Mesh Surface>Through Curves command. This is fun

part, as you can play with this command and get various shapes just by using

different options in drop down menu. You can play a little with editing these

extrusions to get different shapes of through curves surface.

Note that I didn't

use tangent to second extrusion surface, after fey tryouts I found that this is

best shape for this helmet.

Now we will trim this

shape before adding thickness on it. I draw a line parael to X axes, from corner

of shape, so I can use that line as axe for my datum plane. Through that line

make a datum plane at angle of 13-15 ° from XY plane.

Make new datum

pane parallel to one we just made, and on 15mm distance from it, and use it to

trim shape we got with through curves

command.

We can offset this shape to get first part of our

model. This will be part of helmet that come right next to our head, so you

need to offset it from your head to make place for comfort liners, and to make

it in thickness of plastic you will use for this part. Use Insert>Offset/Scale>Thicken

command.

Now we have to make openings for your nose and eyes. Make new sketch that look

like this:

Part of sketch that

come near face is optional, and it size and shape depend on type of stripes you

will use for this helmet. Be careful to make enough room that you can put your

head in this helmet!

After making this

sketch, make extrusion of it and use intersection Boolean option with head

shape made with thicken command.

We will start

making outer shape of helmet. Use Thicken command again.

NOTE: for all thicken

commands in this tutorial we will use Through Curves surface shape as base

shape.

If you know how much

space electronics equipment for this helmet will take then make outer offset to

your calculations, and inner offset is smaller for thickness of plastic you

will use to make this helmet.

We will trim this part

3 millimeters less then inner part but you can make it as you like.

New sketch, this

define all outer shapes. We will call it Main

Sketch in this tutorial

Now extrude part of

outer lines of sketch that define shape of helmet

I use offset to

surfaces that are almost tangent to gray colored shape so we do not have

problems with Boolean functions on it.

And we use intersect

command on it to make shape of helmet.

So far this is what

we have:

New Thicken,

this one is for back side of helmet.

New sketch with shape

of back side of helmet:

Again intersection of

these two parts to get what we need:

For now we have part

that come near head, outer shape of helmet and back side of helmet. Before we

make glass or transparent plastic part, we need to make outlets that will

support transparent part of helmet.

New Thicken,

this time first offset have to be for thickness of plastic smaller of outer

shape, and second offset for same amount smaller then first offset.

This is what we get:

Now use lines of Main Sketch to make sheet extrusion

Add Thickness

to this sheet. First offset is with how much material it will be joint to outer

shape of helmet and second offset is how large outlet will be. I think that

depend on type of connection you will use to join helmet and “glass”.

Now intersection of

last two features:

Here you can see how

this outlet look when finished:

Now “glass” (this

will be some kind of transparent plastic, but I will call it “glass”) Thickness.

It have to be same as outer shape of helmet.

Trimmed with same

sheet we used to make outlet feature.

Now we need to make “ears”

and colored lights to finish this tutorial.

One more time make Thickness,

offset for this one depend on how you will make colored lights, so I made it

only 1mm. you will have to make it in size of boxes you will put lights in. Dimensions

of this Thickness is all up to your design!

I made it to touch

outlet for “glass”, you can make it to touch “glass” or you can left space between…it's

all up to your design.

We have to cut

out center section of this part, make a sketch with rectangle, width of

rectangle should be big enough so you can have good sight from this helmet, so I

think minimal should be as width of outer corners of your eyes, or width of

your temples.

Extrude this sketch

and subtract feature you get from thickness feature you made earlier.

As this part of design is depending on your solution of light boxes, I will

use sheet I used for outlets to trim it. You will use some other construction

feature depending on your light box design!

Now we will make “ears”

for this helmet.

To do it we need to

make some planes and to make planes we need new sketch in XZ plane (in

this case I know it is plane of maximum curve of this model so I will use this

plane, in case you do not know where is maximum you will have to find it first

and then to make sketch trough that plane). This time you have to use Intersection Curve command

to add intersection line of sketch plane and outer helmet shape (gley dot-dash

line). Now draw two lines one horizontal and one vertical, this lines will help

you to find where the point of maximum distance of model from YZ plane is. Make

vertical line tangent to intersection curve, and make horizontal line touch

vertical line in intersection point of vertical and intersection curve. Now exit

sketch.

To make this plane in

one click you just select ending point of horizontal line, that way datum pane

command will have both axes and point for new plane.

Make new plane on

some distance (and parallel to) from previous one.

We will now use Main Sketch.

We will use it to make “ears”.

Now use outer ear

line to make extrusion.

Trim extrusion with outer

surface of helmet.

And with last plane

we created.

Draft new feature from

plane that is tangent to helmet outer surface (plane we got from sketch line)

Unite this feature to

helmet.

Now make new

extrusion of second “ear” curve from sketch we used in previous step. This

extrusion will be From Extended, select plane that we use

to trim previous feature, for end put any distance that get new extrusion out

of helmet parts we have so far.

Now make offset of

side of feature closer to helmet, this feature we will subtract from helmet so

we get pocket, enter offset value you like.

Now subtract new

feature from helmet.

So we now have

pocket:

Draft that pocket a

little,

To get this:

Now extrude circle

form sketch, make it start on face of pocket and end it where you like.

Now draft that

extrusion;

Unite it with helmet and

we are almost finished with outer helmet shape;

Blend some of sharp

edges a little;

I forgot to unite helmet

with outlet, so I will do it now.

Make

shell of helmet. I used 3mm, it is the plastic thickness I used for all parts

of outer helmet shape.

Now we will cut part

that represents lights. Make planes from axes that come trough center of

circular shape of “ear”, how many and at what angle depend on your design of

light boxes.

Use Split

Body command to make different colored boxes.

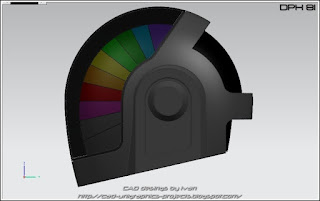

I colored spitted

parts.

Use Insert>Associative

Copy>Instance Geometry to make mirror of all solid bodies we made so

far.

And we are done with

this tutorial!

I hope you had fun!

As fun is most

important part of everything we do!

If you produce this helmet

using this tutorial please send me images so I can add them to this post!

Thank YOU for staying

with me till the end! !

I need a Daft Punk helmet cad file. Is there anyway I can get one from you?

ReplyDeleteyou can downland CAD files on next post http://cad-unigraphics-projects.blogspot.com/2011/08/daft-punk-3d-model-free-cad-download.html

ReplyDeletei need an application to download either model what application do i need

ReplyDeletedownload SolidWorks eDrawings 2011, it is free viewer for 3D CAD files in .stp and .igs formats, you can open few more formats with it :)

ReplyDeletecan i have the solid works version of your file?

ReplyDeleteSorry Eagon, I can't convert this model to SolidWorks format, NX can't do that, and I do not have SW installed to try to recreate it in SW...

ReplyDeletei am an beginer in nx, can u give any moderate drawings for practice.

ReplyDeletemy id balaji.c.aero@gmail.com

it will be helpfull for me

Alright im going to machine out your model at a small 3inch scale and then use your tutorial next semester to make my own full scale thanks! can you make a tutorial on how to make a thomas bangalter helmet too?

ReplyDeleteHi Eagon, have you done it? Can you share some images?

Deletesorry EAGON i do not have time for that model right now. i had plans to make that one too, but too much other things to do :)

ReplyDeleteCan you please tell me where i can download a head shape like the one you used?

ReplyDeleteI can't believe i actually skipped whole year without answering...

Deletesorry, i can send it to you if you need it after such a long time.

hello

ReplyDeletei m french and a work in cnc machin

look my projet

http://www.youtube.com/watch?v=cYVlUOtrS24

http://imageshack.us/photo/my-images/707/sam4034.jpg/

http://imageshack.us/photo/my-images/6/sam4091a.jpg/

Tank

Nice video!

Deletedid you made CAD model yourself or just work on CAM?

hello Ivan

ReplyDeletei have topsolidcam7

i work cao and cam

tanks

I ripped of the Daft Punk Helmet pretty quick my sketches are not as nice as yours, but it turned out ok. pic.twitter.com/oydLHHAuSX

ReplyDelete*off

Deletenice model, looks great. what software you used to make this model?

DeleteUnigraphics NX 7.5

DeleteNice!

DeleteYou are pro or student?

I took Mechanical Engineering 3 year advanced course. I finished in 2007. I just play around with Unigraphics on my spare time to keep my cad skills sharp.

DeleteInfo on Jewelry design CAD software , Rhino and Flamingo,how do you like them?

ReplyDeleteSolidworks Course

http://youtu.be/GpiyT2DBLSM

ReplyDeleteThank you for link Tim!!

http://youtu.be/GpiyT2DBLSM

ReplyDeleteThank you for link Tim!!

Hey Ivan, I was wondering if you could tell me where I could find small, medium and large head models (preferably for Solidworks)

ReplyDeleteHey Ivan,

ReplyDeleteI was wondering if you knew where I could get a head model like that? Preferably for SolidWorks and it would be great if there were small medium and large sizes

Hello Jeremy, I got this from my friend, and he told me that he made this head models in NX. So i do not have any other format but NX part. I will try to convert this to parasolid or iges and to put them on my blog, but sometimes this kind of models become huge and useless if you convert them to parasolid, i will see how it will come out.

DeleteThis is a minor comment about the structure of the AEC (UK) BIM Protocols. The way in which the sections are numbered the same in all documents is very useful for cross referencing.

ReplyDeleteIt might be worthwhile putting a section called ‘Document Structure’ in the Introduction to explain why you have done this to ensure people don’t overlook it.

Sorry but I have no idea what are you talking about?

Delete