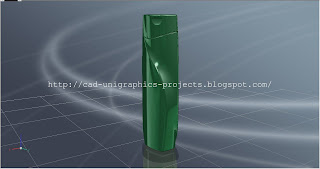

Shampoo bottle

Designed in Siemens NX

This is one 'just for fun' project. it started as bet "you can't make it like this without CMM" (Coordinate Measuring Machine machine that 'scan' 3D points of objects so designers can use them to recreate parts) it end as mold design tryout.

This is one 'just for fun' project. it started as bet "you can't make it like this without CMM" (Coordinate Measuring Machine machine that 'scan' 3D points of objects so designers can use them to recreate parts) it end as mold design tryout.

On pictures below you can see original bottle and my CAD design.

I started with ruler and felt pen, draw parallel lines to make sections on bottle.

Then i use ruler and caliper to measure curves for making rough model.

Then added bland where needed, and with few more mouse moves i got:

Then it was time to take off bottle top. And to model top of the bottle.

After that i did analysis of bottle surface, to see if it is smooth as it look like (this is done because our eye and computer resolution do not allow us to see some deformations on object surfaces, especially on rounded edges and small surfaces)

And now here is finished model of bottle and cover.

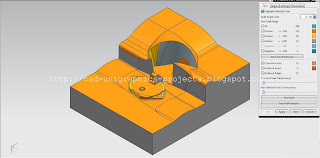

After few days i decided to try to make cast tools for this bottle, i started with cast tool for cover. I designed four part tool for cover with open lid. it have two half which form lid and outer contour of lid, then core for inner contour and one small core. next are pictures of side view, side view in perspective, and trimetric view on cast tool.

After I finished model i made analysis to assess moldability and manufacturability.

This is very nice. As far as I know the bottle has to be blown. Does Unigraphics know how to do this?

ReplyDeleteYou are mentioning making analysis of moldability. How did you know the material, pressures and temperature used in molding it?

Hi Stefan,

ReplyDeleteYes You are right, bottle has to be blown, and as i do not know that process I only made tools for bottle cap, not for bottle itself, so i do not know details about NX and blowing mold design. In analysis of moldability I didn't go to far (i just checked if angles of tool parts are good), as it was just for fun project, but as far as i know nx have all tools for building and all needed analysis of tools for molding.

Hi everyone,

ReplyDeleteI bet with you than I can do it for good price of course. You can send me some sketch of bottle and I make it for you.

Best regards

Mladen

"Bet you can't make this." is how I started this bottle project, my friend who know I make rockets wanted to prove me that I am not good enough in CAD to make this bottle, so I had to prove him wrong. It is not a challenge to people who read this post, just sentence that make this 3D model design started.

ReplyDeleteFantastic job. Well done.

ReplyDeleteJust a few questions is that a variable blend you used to create a smooth surface? and did you build this CAD model from a solid or using surface modelling.

Did you record a tutorial on how you built this CAD model. If so could you provide a link. I'm sure I can learn something from this.

Thanks

Mike

I cut solid with surfaces, it was easier then to trim surfaces and saw them. Yes almost all blends on bottle are variable blends.

ReplyDeleteI wasn't intended to make tutorial from this, so all I can do is reconstruct design using Part Navigator History. But it would take time to do that. As i remember i started this bottle three times, before i get to right path. First step of making that basic shape was hardest.

But I can promise that i will try to make tutorial about designing that basic shape when i have enough time to do it.